The Wolverine Company of Rockford

and the Krause Family

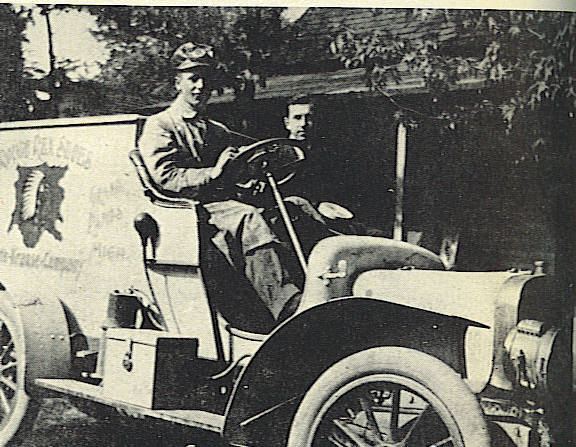

Ben Krause - Hirth-Krause Company

Victor W. Krause Adolph K. Krause

Richard H. Krause

|

The beginning of the Krause family's involvement in the leather tanning business. Valentin Krause returned from

fighting in the Napoleonic Wars to become a tanner in his home, Thierenga,

Prussia. His son, Henry, who was born in 1820, served his apprenticeship

in his father's tannery. When 21 years old he emigrated to Ann Arbor,

Michigan. Henry and his brother-in-law established a tannery there.

In 1850 he won the first prize for Superior Upper Leather at the Michigan State

Fair. In 1903, after twenty years, a shoe factory was built in Rockford on the banks of the Rogue River. O. A. Krause, the eldest son of G. A. was at the helm. Victor Krause, brother of O. A. joined the company in 1908. His training was in tanning and the next year a tannery was built. Their slogan was, "Wolverine Shoes ... From Hide to you." At this time the manufacturing company was known as Michigan Shoemakers with the name "Wolverine" selected for brand identification. In the early years research was begun in tanning Shell Cordovan horsehide, a tough long-wearing leather. This leather was also used for gloves. Concentrating on the Shell Horsehide leather, the company was able to grow even during the depression. One of the innovative ways - they used large quantities of bacon rind which resulted in producing Suede Pigskin leather. They prepackaged bacon in the early thirties. The coming of the tractor had effect on tanners of horsehide leather - fewer horses, less horsehide. They then turned to "green" (unsmoked) pigskins. Hundreds of thousands pigs were killed each year, only a fraction of the pigskin became leather. This was partly due to the difficulty in removing the skin without damaging it, the skinning process had to be done at the packing plants. Wolverine's tannery research spent seven years in solving this problem. Resulting in a machine to do the skinning. They worked with meat packers making sure the machine would fit into methods used in packing plants. The result a quality shoe leather that is also soft and supple. Employees of the company stay with the company. One of the reasons, in 1921 a plan paid a cash bonus from the profits to employees. Except for two years during the depression, profit-sharing bonuses have been paid to employees. |

Created: 3 January 2008