Part V - Government, a supplement to the Big Rapids Pioneer Newspaper. Used with permission.

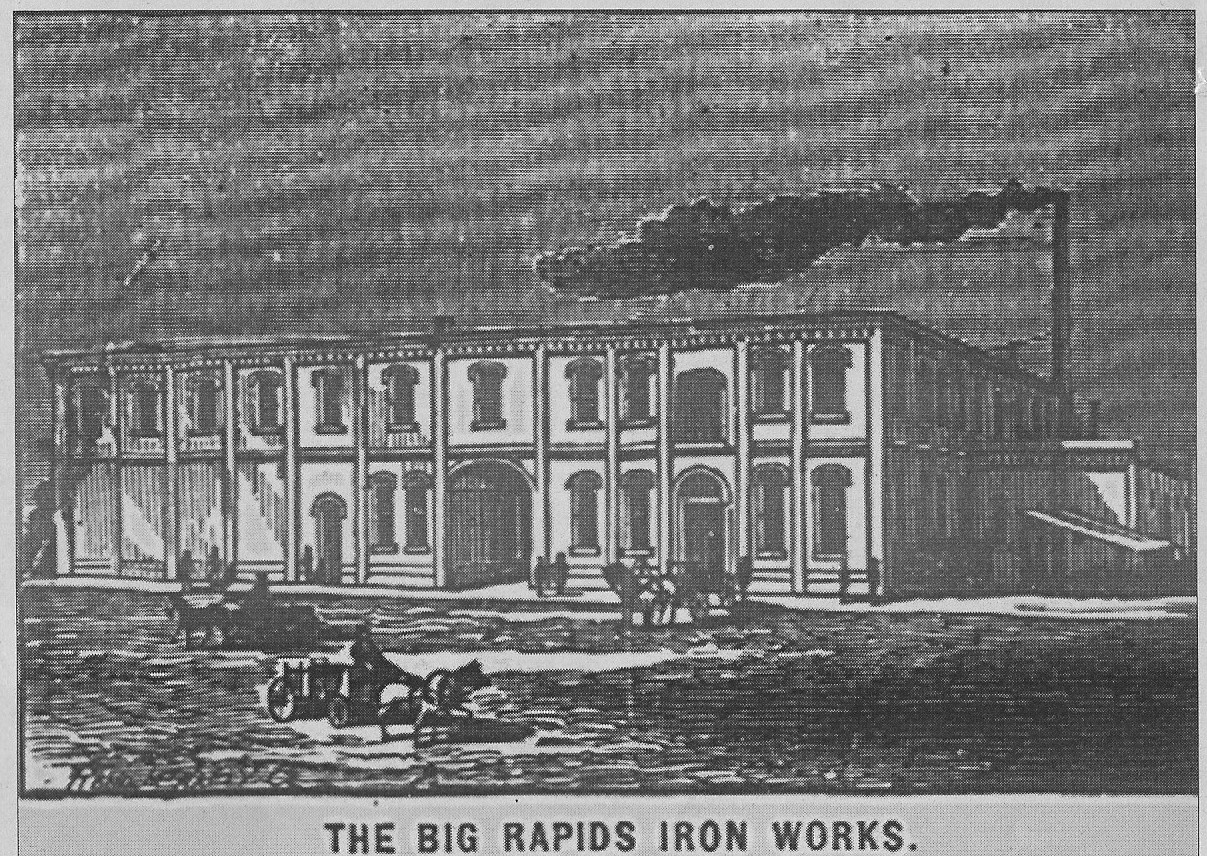

BIG RAPIDS IRON WORKS BECAME THRIVING BUSINESS FOR FAIRMAN

By Jim Bruskotter - Managing Editor

Ferdinand Fairman, the man responsible for the construction of the Fairman-Newton Building in 1880-81 was an investment banker whose dealings in the investments of the times actually played a part in the final design of the building.

Fairman began construction on the new brick edifice on May 20, 1880. The business, office and apartment complex was completed by July 21, 1881, complete with a banking facility for Fairman's investment concerns.

The new building was located on the site of the second hotel in Big Rapis ... the Montreal House, which was erected in 1860 by Augustine N. Williams.

The name was changed to the Mason House after it was purchased by Alfred Mason and became the premier hotel in the fledgling city built at the Big Rapids on the Muskegon River.

The hotel survived a disasterous business district fire on April 26, 1869, but succumbed to the work of an arsonist on Oct. 19, 1879, setting the stage for construction of the facility for Fairman, a building that has now been remodeled to provide housing for area senior citizens on the upper two levels.

Ironically, this particular story of Fairman's involvement in the investment industry did not materialize until construction workers uncovered two iron columns on the outer wall of the west side of the building while remodeling the building for senior housing.

The columns sparked the interest of area historical buffs, including Jim Wood of Millbrook who uncovered a tale that tied the columns to a major industry of those early years.

Thiose columns, and many others throughout the 150 feet by 100 feet, multi-story structure were made at the Big Rapids Iron Works, which was under construction in 1873 as the Peninsular Hardware Manufacturing Co., according to a Mecosta County Pioneer account of Aug. 7, of that same year.

Wood's research shows the firm was constructed by Frederick L. Barker, a distinguised veteran of the Civil War, and his father Jesse Barker, a former supervisor of Green Township, for the primary purpose of producing tools and equipment for the logging industry.

Fairman ended up owning the business when he foreclosed on an 1875 loan to the two men in 1878, ending an unsuccessful venture for the Barkers that cost the elder Barker the family farm, as well, and sent both families for a new life in Crawford County.

Fairman, however, was able to turn the business around and cash in on his investment.

Fairman's obituary in the July 3, 1902 Pioneer details some of the story: "In 1876 (date varies in different accounts) Mr. Fairman loaned a considerable amount of money to the parties controlling the Big Rapids Iron Works, securing himself a mortage. The affairs of the concern became involved, and Mr. Fairman foreclosed in 1878. He at once entered upon the work of running the plant, ane managed the business successfuy, building up a credible trade. In Oct, 1881, he sold the establishment to 'George M. Gotschall and Edwin Cannon ...."

Ironically the sale to Gotschall and Cannon come right after the completion of the Fairman and Newton Block, complete with iron support columns produced at Fairman's own manufacturing company only three blocks to the north.

Another more detailed account researched by Wood comes from the March 10, 1881 edition of the Big Rapids Pioneer-Magnet.

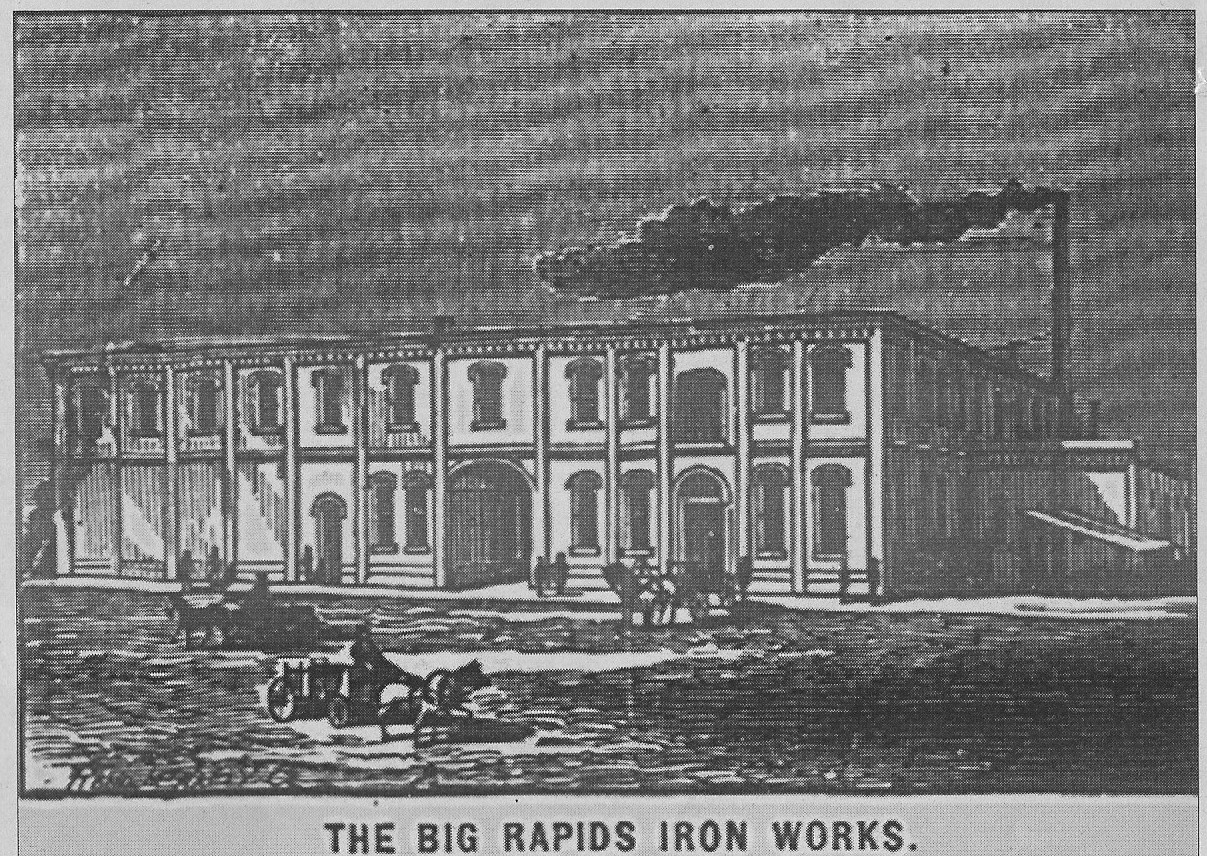

"As might be expected," the article begins, "the large number of mills in this region afford a vast amount of iron work for machine shops. The largest establishment of the kind in this city, and in fact one of the largest in Western Michigan, is the Big Rapids Iron Works, now owned and controlled by F. Fairman. The concern was established some eight or nine years ago, but mismanagement and the hard times following the panic of 1873 made it an unprofitable investment for its founders.

"After a somewhat checkered career, it passed into the hands of Mr. Fairman, and a revival of prosperous times makes it a valuable piece of property. The works are advantageously located on the west side of Michigan Avenue, but a short distance from the Chicago & West. depot, and when is connection is made between road and the D.L.& N., the track will pass near them, affording the very best of facilities for railway shipment.

"The works comprise two brick structures, standing in the form of an L, one being 50 by 100 feet, bith two stores high. They are equipped with all kinds of machinery for carrying on the business which is propelled by steam power.

"Special attention is given to the manufacture of steam engines, gang edgers, steam drag saws, logging cars, and all kinds of lumber and shingle mill machinery, as well as repairing anything and everything used about any and all kinds of mills.

"The works are abundantly supplied with all the various parts of the celebrated Stearns mill machinery, and an order for any particular piece or part can be filled at a moment's notice.

"Iron columns for building fronts are also one of the specialties of these works. The large amount of casting done requires a heat to be taken off as every other day, and much oif the time every day so that if any particular casting ordered is not in stock, it can be made the same or following day, which is sometimes a great convenience to mill owners.

"Three hundred logging cars, worth a $100 each, were among the work turned out during the past year. A large steam engine for S.H. Gray & Co.'s enlarged shingle mill has recently been built there.

"Mr. Fairman commenced operating the works Dec. 1st, 1878. His first years business aggregated about $20,000. The second year went up to $60,000, and the opresent rate warrants the belief that the third years business will exceed $100,000. This is certainly a very gratifying increase, both for the proprietor and the country round-about, as it indicates a very satisfactory development of business in this region.

"Since the works have passed into Mr. Fairman's hands, they have been thoroughly overhauled, repaired and equipped. The latest addition is a set of Buffalo scales, with combination beam, which will weigh 9500 lbs at a time. They will be put in as soon as the frost is out, so an excavation can be made for them.

"The works give employment to 30 men when running day time only, and 40 when running day and night, which they do about four months out of each year.

"During the oast winter, a press of work has made it necessary to run over time, generally about 14 out of each 24 hours. Employees are paid in cash on the 10th of each month the payroll averaging $1500 per month, the year round.

"Mr. Fairman says that his employees are instructed to turn out the vey best work possible, at lowest cash prices, and to make no promise that cannot be fulfilled in time, that customers may not be disappointed."

According to Wood the Big Rapids Iron Works burned down in 1889.

Return to Mecosta sesquicentennial Page

Return to Home Page