of Pioneer Settlers of Allis

Part VI

Submitted by Nute Chapman

From Onaway Outlook February 1, 2013

|

of Pioneer Settlers of Allis Part VI Submitted by Nute Chapman From Onaway Outlook February 1, 2013 |

|

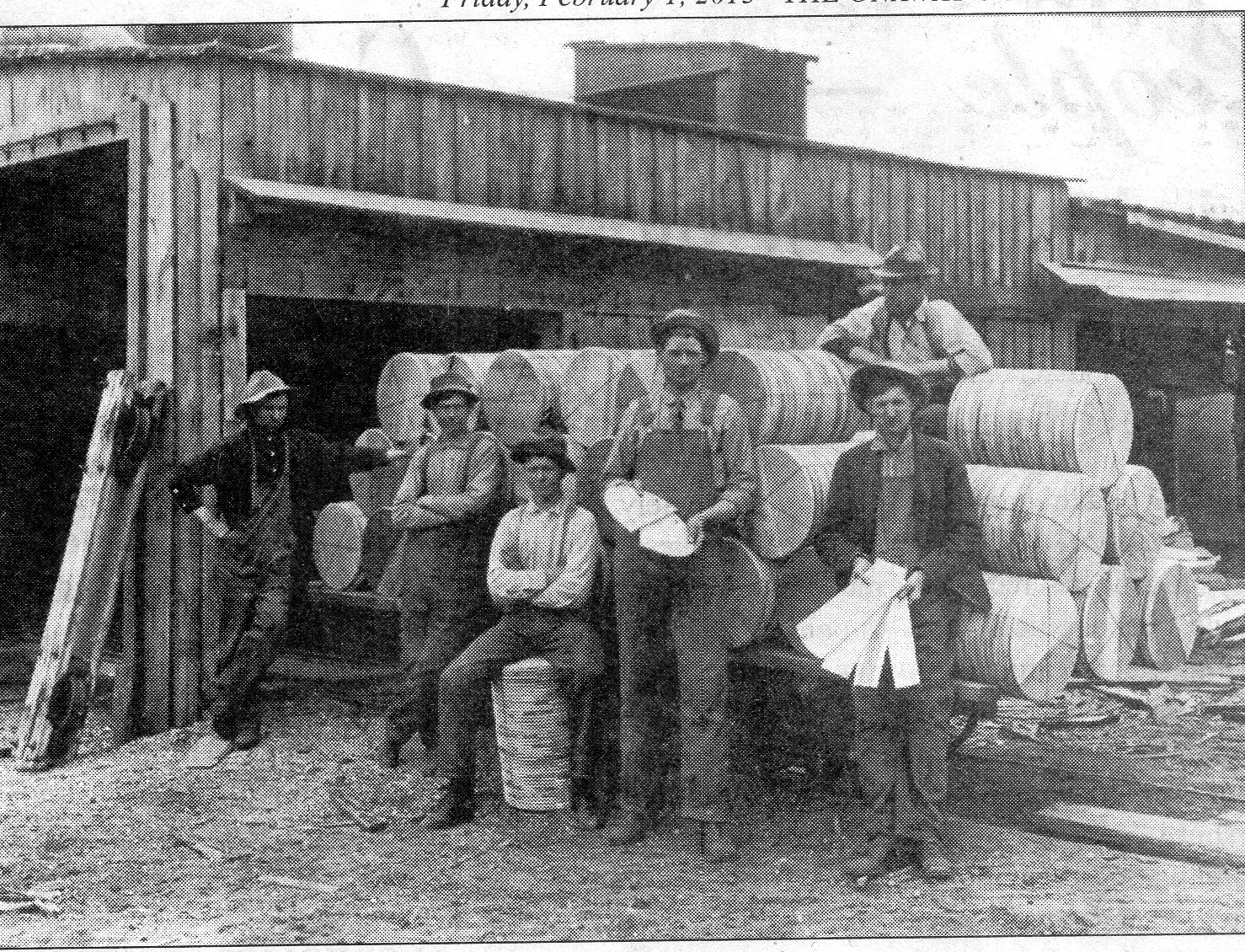

CAPTION #1: THE MAHONEY MILL was located where Ellenberger Lumber Company stands today. Arland Minser, Uncle Harry

and his father Charles Minser are included in this picture.

Unpublished by Oscar Adelbert Roberts and edited by daughter Ruth (Roberts) Schmidt Part VI

Unpublished by Oscar Adelbert Roberts and edited by daughter Ruth (Roberts) Schmidt Part VI

Father Buys A Shingle Mill

I guess he just couldn't help it. It was at a giveaway price. Our land was not what it should be for farming, and

my father had a lot of "mill business" in his blood. He just couldn't help it. My older brothers Jim, John and

Charlie were no longer at home.

Homer and I were big enough to pack shingles, and it was a lot more interesting then weeding onions or hoeing

corn.

The mill consisted of a 40-horsepower marine boiler; a dandy 8-foot by 10-foot horizontal engine; an upright

automatic shingle machine; a drag saw; two knot saws; two packing boxes; and two wheel jointers, a heavy five-foot

disk with four planner blades on its face.

It was a wicked thing. It could eat up a shingle as fast as one could push it. If one was careless, his shingle

was narrowed to nothing. But careful was the word. No one lost any fingers.

All this machinery was hauled from Cheboygan on sleighs, and set up on the southwest corner of our clearing, just

beside Stoney Creek, where we had lots of water. After the machinery was set up, a log building was built around it.

We made beautiful shingles of black ash. When dried out they looked like tile on a roof when it rained and they laid

flat.

The sawmill was good, and we sold a lot of shingles. But as time went by, conditions around home became unbearable.

Mother had died a couple or so years before, and father had married a woman from Cheboygan at about the time that he

bought the mill- to keep house for us.

Two years later, the mill was sold to Mr. Slater, who worked for us in it. He found that he couldn't pay for it so

father sold it to Kelly Williams in Tower. I was to go to help set up the mill. I stayed all winter, running the engine

and as foreman. We men kept "batch" that year. One man was too old to work much. He drank the water our food was

boiled in; he said it was good for him. He was a fine old fellow. He and I were the cooks.

The first winter after that, I worked in "Dorce and Dickinson's" Store and Heading Mill wheeling bolts, elm blocks,

which were 5 or 6 inches square. These bolts were put in airtight steam boxes 8 feet by 10 feet and live steam turned

on until the chunks of wood could cut like butter. They were cut by a power knife into barrel staves, and piled into the

yard to be trimmed later with a foot-power knife.

Both operations were very dangerous work. In February it became so cold that the mill was shut down for two weeks as they

couldn't steam the bolts soft enough to cut into barrel staves.

-From The Onaway Outlook, February 1, 2013, p 3.

Retyped by J. Anderson.